Trouble Shooting – Battery and Ignition Cables

Battery

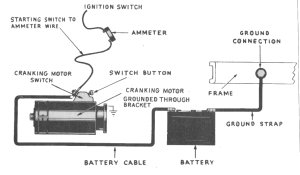

Battery failure is usually discovered when the cranking motor fails to operate. A simple, positive check of battery condition can be made with a hydrometer. If this test shows that the battery is fully charged, there may be a loose or broken cable. Defects that are not revealed by visual inspection can be localized by making line voltage tests.

Since the acid in the battery electrolyte decomposes as the battery discharges, the weight of the electrolyte gives a direct indication of the state of charge. This weight, or specific graveity, is measured with a hydrometer. To be accurate, the reading must be taken when the bettery is filled to the normal level (⅜ in. above top of plates), but do not test the specific gravity for several hours after adding water. At extremes of temperature it is important to correct hydrometer readings to allow for this variation. The normal standard is 80°F. Add 0.004 for each 10° below standard.

Test each cell with an accurate hydrometer. Each cell of a fully charged battery should read between 1.260 and 1.300. Under normal operating conditions the battery should be removed and recharged if the reading is below 1.225.

Inspect for cracks in the cell covers and containers or for cracked or chipped sealing compound. Slight cracks in sealing compound can be repaired by brushing lightly with a blow-torch flame (Editor’s Note: This may have been and accepted practice in the 40s but a battery generates hydrogen gas and could explode when exposed to flame or sparks.) Cracks in cell covers and container and serious cracking of sealing compound require replacement of the battery.

Battery

Battery failure is usually discovered when the cranking motor fails to operate. A simple, positive check of battery condition can be made with a hydrometer. If this test shows that the battery is fully charged, there may be a loose or broken cable. Defects that are not revealed by visual inspection can be localized by making line voltage tests.

Since the acid in the battery electrolyte decomposes as the battery discharges, the weight of the electrolyte gives a direct indication of the state of charge. This weight, or specific graveity, is measured with a hydrometer. To be accurate, the reading must be taken when the bettery is filled to the normal level (⅜ in. above top of plates), but do not test the specific gravity for several hours after adding water. At extremes of temperature it is important to correct hydrometer readings to allow for this variation. The normal standard is 80°F. Add 0.004 for each 10° below standard.

Test each cell with an accurate hydrometer. Each cell of a fully charged battery should read between 1.260 and 1.300. Under normal operating conditions the battery should be removed and recharged if the reading is below 1.225.

Inspect for cracks in the cell covers and containers or for cracked or chipped sealing compound. Slight cracks in sealing compound can be repaired by brushing lightly with a blow-torch flame (Editor’s Note: This may have been and accepted practice in the 40s but a battery generates hydrogen gas and could explode when exposed to flame or sparks.) Cracks in cell covers and container and serious cracking of sealing compound require replacement of the battery.

If removal is required, first disconnect the ground strap to avoid a short if the wrench strikes the frame while removing the cable to the starting motor. If the bolts and nuts are corroded, hold the terminal with pliers and use a wrench on the nuts. This prevents damage to the battery posts. IF the terminal clamp is not easily released, insert the screwdriver edge of a pair of pliers into the open end of the terminal yoke and twist to release the yoke. Do not hammer the battery post to release the terminal. Do not place a screw driver or other tool under the terminal and pry up on the terminal — this might break the cell cover.

Before installing the replacment battery, make sure the carrier is free from corrosion and has no tools or rocks in it. A tar-base paint can be applied to the carrier to assist in preventing corrosion. Determine the correct location of positive and negative posts before placing the battery in the carrier. The positive post is larger — may also be identified by a “+” or “POS” marking or by red paint on the top surfaces.

If considerable corrosion has been encountered, washers cut out of felt may be slipped over the battery posts, the cables installed, and then the washers saturated with oil. After the terminals have been installed, a light coat of chassis grease may be applied around the correction to prevent corrosion.

When installing the cable terminals, tighten the nuts carefully. Be sure the bolts are long enough to allow each terminal to fit the post correctly. Tighten the hold-down bolts so that the battery cannot shift in the carrier. Take care to avoid unnecessary tension that might crack the case of the battery.

After the terminals have been tightened, check the installation by turning on the headlights with the engine not running. The ammeter should register discharge. IF the ammeter registers charge, remove the battery and install it in the reverse position so that terminals can be connected correctly (Editor’s Note: This presumes that you jeep was wired correctly – if you have just rewired the jeep, suspect the ammeter not the battery).

Special Operating Conditions

When batteries are operated in tropical climates where freezing temperatures are never encountered, the full-charge specific gravity is reduced to the value between 1.210 and 1.225 by dilution with water. Under these circumstances, a tag should be attached to the battery to show the full-charge specific gravity.

Battery capacity is greatly reduced by low temperatures. At 0°F the battery has only 40 percent of the cranking power it has at 80°F. Special care must be taken to keep batteries fully charged, but do not attempt to adjust specific gravity to values above 1.300. At temperatures below -20°F, batteries must be heated during periods of operation and stand-by.

If removal is required, first disconnect the ground strap to avoid a short if the wrench strikes the frame while removing the cable to the starting motor. If the bolts and nuts are corroded, hold the terminal with pliers and use a wrench on the nuts. This prevents damage to the battery posts. IF the terminal clamp is not easily released, insert the screwdriver edge of a pair of pliers into the open end of the terminal yoke and twist to release the yoke. Do not hammer the battery post to release the terminal. Do not place a screw driver or other tool under the terminal and pry up on the terminal — this might break the cell cover.

Before installing the replacment battery, make sure the carrier is free from corrosion and has no tools or rocks in it. A tar-base paint can be applied to the carrier to assist in preventing corrosion. Determine the correct location of positive and negative posts before placing the battery in the carrier. The positive post is larger — may also be identified by a “+” or “POS” marking or by red paint on the top surfaces.

If considerable corrosion has been encountered, washers cut out of felt may be slipped over the battery posts, the cables installed, and then the washers saturated with oil. After the terminals have been installed, a light coat of chassis grease may be applied around the correction to prevent corrosion.

When installing the cable terminals, tighten the nuts carefully. Be sure the bolts are long enough to allow each terminal to fit the post correctly. Tighten the hold-down bolts so that the battery cannot shift in the carrier. Take care to avoid unnecessary tension that might crack the case of the battery.

After the terminals have been tightened, check the installation by turning on the headlights with the engine not running. The ammeter should register discharge. IF the ammeter registers charge, remove the battery and install it in the reverse position so that terminals can be connected correctly (Editor’s Note: This presumes that you jeep was wired correctly – if you have just rewired the jeep, suspect the ammeter not the battery).

Special Operating Conditions

When batteries are operated in tropical climates where freezing temperatures are never encountered, the full-charge specific gravity is reduced to the value between 1.210 and 1.225 by dilution with water. Under these circumstances, a tag should be attached to the battery to show the full-charge specific gravity.

Battery capacity is greatly reduced by low temperatures. At 0°F the battery has only 40 percent of the cranking power it has at 80°F. Special care must be taken to keep batteries fully charged, but do not attempt to adjust specific gravity to values above 1.300. At temperatures below -20°F, batteries must be heated during periods of operation and stand-by.