Timing Marks Made Easy

Dear Editor,

H.M. Johnson, Automotive Advisor, 70th Signal Co., Camp Butner, N. C.. complains, as many another mechanic before him has complained, that the location of the inspection hole on the 1/4-tan truck, makes it very hard to observe, the correct position of the timing marks.

Constructively, Mr. Johnson comes forth with an idea on “relocating” the timing marks which will make checking the timing marks a thing of beauty and a joy forever. Since the fan pulley turns as the flywheel turns, Mr. Johnson center-puncbes a mark on the pulley and uses that mark, which con be more easily seen than the one in the inspection hole, as a timing mark.

Here’s the idea in three easy steps:

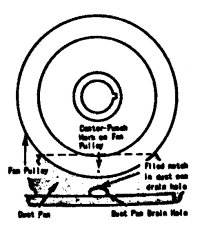

Remove the inspection hole cover and line up the IGN mark on the flywheel with the mark on the flywheel housing.

Proceed to the small dust pan directly beneath the fan pulley. There’s a small drain hole in the bottom of this dust pan. Take a three-cornered file and notch this drain hole as shown (see fig.). This notch will serve as a stationary timing mark.

Now make a center-punch mark on the fan pulley directly above the mark as the small drain hole. — being careful not to let the engine turn.

This center-punch mark and the mark on the drain hole now exactly “reflect& the correct position of the marks on the flywheel and flywheel housing, if you have transferred them exactly.

We can’t stress too strongly that you’ve got to transpose the marks faithfully — otherwise you’ll ne setting the timing by screwy marks and consequently, your timing will be off.