AS A COMBAT FIELD FIX, THIS LITTLE BOX UNDER THE HOOD PINCH-HITS FOR YOUR SHOT-TO-HELL MUFFLER AND EXHAUST PIPE

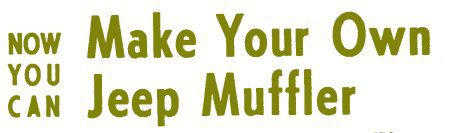

Lay out your sheet metal and cut a piece l0″x12″. Measure 7″ from the right edge of the l2″ width of the metal and drill a 1 5/8″ dia. hole (see Fig. 1) about 1/4″ from the bottom. The tailpipe?ll fit into this opening. Then form the sides of your box (Fig. 1) by bending the piece of metal at right angles (over a sharp edge, like a vise) to a shape 10″ long, 4″ wide, and 2″ deep.

Cut out two 2″x4″ plates (see Figs. 2 and 3) for the top and bottom of your box. In one plate, drill a 1 5/8″ dia. hole (Fig. 2) so the edge of it is about 3/16″ from the end of the plate. This provides the opening for your flange and pipe. Cut two more plates, both 1 7/8″ x3 7/8″ (see Figs. 4 and 5). In p1ate #4, drill three 5/8″ holes; in plate #5, drill twenty 5/16″ holes. These plates?ll fit inside the box, and the holes are what?ll baffle the sparks and muffle the sound of your exhaust.

Lay out your sheet metal and cut a piece l0″x12″. Measure 7″ from the right edge of the l2″ width of the metal and drill a 1 5/8″ dia. hole (see Fig. 1) about 1/4″ from the bottom. The tailpipe?ll fit into this opening. Then form the sides of your box (Fig. 1) by bending the piece of metal at right angles (over a sharp edge, like a vise) to a shape 10″ long, 4″ wide, and 2″ deep.

Cut out two 2″x4″ plates (see Figs. 2 and 3) for the top and bottom of your box. In one plate, drill a 1 5/8″ dia. hole (Fig. 2) so the edge of it is about 3/16″ from the end of the plate. This provides the opening for your flange and pipe. Cut two more plates, both 1 7/8″ x3 7/8″ (see Figs. 4 and 5). In p1ate #4, drill three 5/8″ holes; in plate #5, drill twenty 5/16″ holes. These plates?ll fit inside the box, and the holes are what?ll baffle the sparks and muffle the sound of your exhaust.

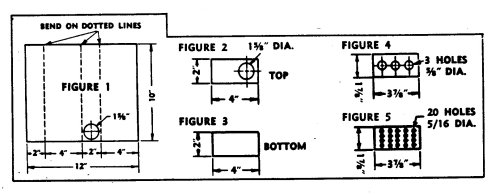

You?re ready, now, to make a muffler out of the box (see Fig. 6). Take plate #5 (with twenty holes) and weld it securely inside the box 3″ from the bottom end (this is the end of the box with the 1 5/8″ dia. hole). Then weld plate #4 (with three holes) on the inside of the box 2″ from the top. You inclose the sides by welding plate #3 on to the bottom of the box and plate #2 on the top (with the hole in the plate to the same aide as the ho1e in the bottom of the box.)

Here?s how you make the tailpipe (Fig. 6). Get a piece of pipe 1 5/8″ dla. x 3 1/2″? long (or make the pipe by welding a piece of sheet metal together), and flatten one end to a 3/8″ opening. Weld the round end of the pipe to the 1 5/8″ dia. opening in the bottom of the box.

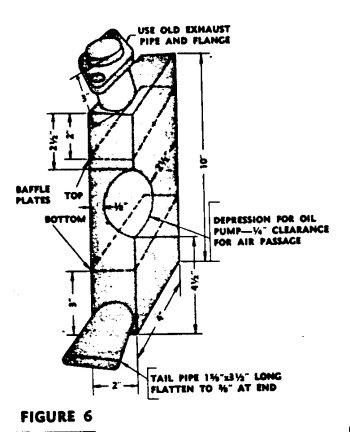

For the bracket, cut a piece of band iron 1/8″ x 1 1/4″ x 6″ (see Fig. 7). Then drill a 3/8″ dia. hole in one end and a 5/8″ dia. hole in the other. Make a right angle bend as shown (Fig. 7). Find a 3/8″ x 16-thread x 3/4″ bolt and weld the head to the side of the box that?s opposite the tail-pipe (see Fig. 8), 3 1/2″ from the top of the box and 1/2″ from the side. Attach the bent end of the bracket to the box with the bolt and a 3/8″ 16-thread nut.

For the bracket, cut a piece of band iron 1/8″ x 1 1/4″ x 6″ (see Fig. 7). Then drill a 3/8″ dia. hole in one end and a 5/8″ dia. hole in the other. Make a right angle bend as shown (Fig. 7). Find a 3/8″ x 16-thread x 3/4″ bolt and weld the head to the side of the box that?s opposite the tail-pipe (see Fig. 8), 3 1/2″ from the top of the box and 1/2″ from the side. Attach the bent end of the bracket to the box with the bolt and a 3/8″ 16-thread nut.

Now your muffler?s done and ready to install. Attach the flange and pipe of the muffler to the exhaust manifold (see Fig. 9) as it was originally, using the same bolts and nuts. In order to fasten the bracket to the rubber mounting (under the fuel pump), remove the nut holding the body support to the mounting, place the bracket end over the body support and attach both of them with the same nut. This finishes the job and you?re ready to go again?but quietly.

If you have trouble with heat from this muffler causing vapor lock in the gas lines, protecting them with a shield will help. Make it from sheet metal, and for better insulation, glue a piece of asbestos on the side facing the muffler. Attach some sort of bracket to the shield and place it between the muffler and gas lines by fastening the bracket under a convenient nut.

There?s going to be a production change soon in the location of the exhaust pipe and muffler on the 1/4-ton. The pipe?ll then extend straight back with the muffler placed as high as possible, approximately under the rear seat. Also the bend will be taken out of the pipe?s flexible section, which?ll make it more flexible and prevent some of the breakage and corrosion at this point