The GP was Ford’s answer to the call to produce a Truck 1/4-Ton 4×4. Nicknames for the little vehicle included Pygmy, Blitz Buggy and Leapin’ Lena, among others. It, the American Bantam Car Company’s Model BRC and Willys Overland’s Model MA were the three pre-standardized “jeeps” built in limited quanties for Army testing. The complete story of how the GP was built is not yet available in pictures, however what follows is a collection of shots from the National Archives that illustrates the production line and testing.

The GP was Ford’s answer to the call to produce a Truck 1/4-Ton 4×4. Nicknames for the little vehicle included Pygmy, Blitz Buggy and Leapin’ Lena, among others. It, the American Bantam Car Company’s Model BRC and Willys Overland’s Model MA were the three pre-standardized “jeeps” built in limited quanties for Army testing. The complete story of how the GP was built is not yet available in pictures, however what follows is a collection of shots from the National Archives that illustrates the production line and testing.

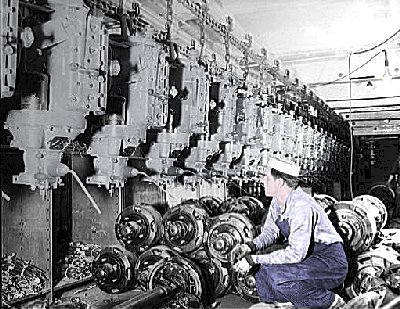

A major sub-assembly of the Ford GP – engine and transmission makes it way along the assembly line in Ford’s River Rouge production facility.

A major sub-assembly of the Ford GP – engine and transmission makes it way along the assembly line in Ford’s River Rouge production facility.

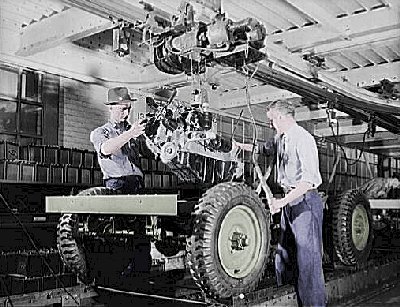

The engine and transmission sub-assembly is lowered on to the waiting chassis.

The engine and transmission sub-assembly is lowered on to the waiting chassis.

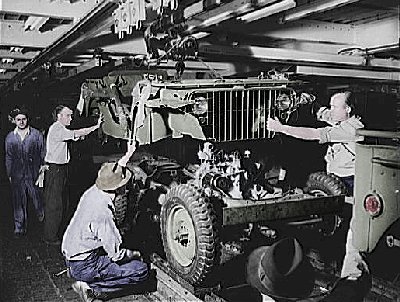

The assembled body is lowered on to the chassis.

The assembled body is lowered on to the chassis.

The nuts and bolts are tighted to hold the body to the chassis. The radiator has been installed, battery installed, the headlights checked and the GP has almost completed its’ trip along the assembly line.

The nuts and bolts are tighted to hold the body to the chassis. The radiator has been installed, battery installed, the headlights checked and the GP has almost completed its’ trip along the assembly line.

The assembled Ford GP next has its’ paint job treated to infrared that causes the paint to dry from the inside out allowing for a “slick” finish. Makes you wonder about the 3 workers also receiving the same treatment!

The assembled Ford GP next has its’ paint job treated to infrared that causes the paint to dry from the inside out allowing for a “slick” finish. Makes you wonder about the 3 workers also receiving the same treatment!

The GP is complete! Now a Ford employee gets to put the vehicle through its’ paces to make sure everything is working. Sure looks like a fun job!

The GP is complete! Now a Ford employee gets to put the vehicle through its’ paces to make sure everything is working. Sure looks like a fun job!

The vehicle is then delivered to the Army and issued for use. In this case the GP has been outfitted with line laying equipment.

The vehicle is then delivered to the Army and issued for use. In this case the GP has been outfitted with line laying equipment.

Even with 4-wheel drive a Blitz Buggy can get stuck. Luckily this driver has a number of willing assistants to get unstuck.

Even with 4-wheel drive a Blitz Buggy can get stuck. Luckily this driver has a number of willing assistants to get unstuck.

The GP going through “rough” terrain but equipped with 4-wheel drive it easily negotiates this obstacle.

Picture Sources: National Archives (online)

The GP going through “rough” terrain but equipped with 4-wheel drive it easily negotiates this obstacle.

Picture Sources: National Archives (online)