From an article by Captain Caesar F. Fiore, Cavalry as published in the Cavalry Journal, March April 1942.

Keep ’em rolling, has been adopted by motorized and mechanized units of our armed forces as their slogan after the National Slogan “Keep?Em Flying.” In order to keep them rolling, particularly in combat and during front-line operations, we of the reconnaissallce elements must learn new and better methods of maintenance, in the realization that our present plan of action is too outmoded and much too slow to produce effective results at a time when speed of the greatest importance.

Maintenance problems in reconnaissance units are in no respect comparable to the problems of other motor units. For example, the present conception of motor maintenance assumes that a disabled vehicle merely pulls over to tbe side of the road and awaits the arrival of the unit maintenance truck. If the unit maintenance section is unable to correct the failure, they move on and leave the disabled vehicle for third echelon maintenance units to come by. This method pre-supposes a definite road of march and vehicles must maintain this road of march in order to receive the advantages of maintenance. Stray vehicles can of course receive aid even if off the beaten path but at best the system is slow and sadly inadequate for reconnaissance warfare.

For reconnaissance elements field maintenance presents a problem in itself. The normal action of a reconnaissance troop necessitates the coverage of an extensive area and as often as not the vehicles are widely separated. A reconnaissance unit to be effective can not be confined to one road but must operate on several and in order to fully acco inplish the mission of reconnaissance it is frequently necessary to dispense entirely with roads and drive cross country.

It is for this reason that the present system of field maintenance must be altered for reconnaissance units. It is neither logical nor practical that a 2 ½-ton truck with boom and winch should go forward to make necessary repairs and replacements in the face of enemy action. The 2 ½-ton truck is too heavy and cumbersome for cross-country driving especially with the enemy in close proximity. Under fire the 2 ½-ton truck offers an excellent and costly target. Lack of speed, armor protection and maneuverability offers little chance of escape to the vehicle or its occupants in case of sudden attack. Furthermore the loss of the 2 ½-ton truck means the loss of priceless equipment and spare parts?enough for the entire troop.

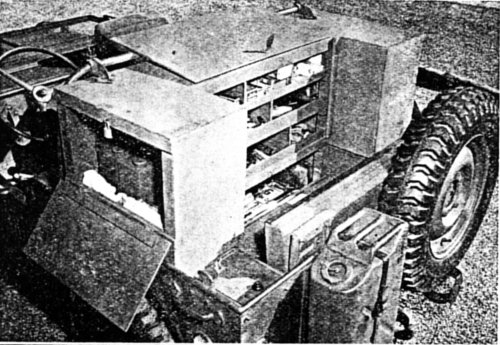

The answer then, lies in that handy little vehicle which has thus far found so many other uses in our Army–the Peep or as some folks would have it the Jeep. In any event the ¼-ton 4 x 4 is the answer to the mechanics prayer. In the accompanying photographs I have tried to show how we have equipped the “Blitz Buggy” with cabinet and a fair supply of tools and spare parts. The result is “Blitz Maintenance.” The principle of using small fast maintenance vehicles in the field is not a new one. Recent G-2 reports accredited German successes in Blitz Warfare to their superior system of motor maintenance, particularly in combat. In short their system is aggressive where ours is passive. By learning some of the secrets of “Aggressive Maintenance” we will gain greater effectiveness and increased efficiency for our reconnaissance units in action.

More

Picture Sources: Cavalry Journal, March April, 1942

Maintenance problems in reconnaissance units are in no respect comparable to the problems of other motor units. For example, the present conception of motor maintenance assumes that a disabled vehicle merely pulls over to tbe side of the road and awaits the arrival of the unit maintenance truck. If the unit maintenance section is unable to correct the failure, they move on and leave the disabled vehicle for third echelon maintenance units to come by. This method pre-supposes a definite road of march and vehicles must maintain this road of march in order to receive the advantages of maintenance. Stray vehicles can of course receive aid even if off the beaten path but at best the system is slow and sadly inadequate for reconnaissance warfare.

For reconnaissance elements field maintenance presents a problem in itself. The normal action of a reconnaissance troop necessitates the coverage of an extensive area and as often as not the vehicles are widely separated. A reconnaissance unit to be effective can not be confined to one road but must operate on several and in order to fully acco inplish the mission of reconnaissance it is frequently necessary to dispense entirely with roads and drive cross country.

It is for this reason that the present system of field maintenance must be altered for reconnaissance units. It is neither logical nor practical that a 2 ½-ton truck with boom and winch should go forward to make necessary repairs and replacements in the face of enemy action. The 2 ½-ton truck is too heavy and cumbersome for cross-country driving especially with the enemy in close proximity. Under fire the 2 ½-ton truck offers an excellent and costly target. Lack of speed, armor protection and maneuverability offers little chance of escape to the vehicle or its occupants in case of sudden attack. Furthermore the loss of the 2 ½-ton truck means the loss of priceless equipment and spare parts?enough for the entire troop.

The answer then, lies in that handy little vehicle which has thus far found so many other uses in our Army–the Peep or as some folks would have it the Jeep. In any event the ¼-ton 4 x 4 is the answer to the mechanics prayer. In the accompanying photographs I have tried to show how we have equipped the “Blitz Buggy” with cabinet and a fair supply of tools and spare parts. The result is “Blitz Maintenance.” The principle of using small fast maintenance vehicles in the field is not a new one. Recent G-2 reports accredited German successes in Blitz Warfare to their superior system of motor maintenance, particularly in combat. In short their system is aggressive where ours is passive. By learning some of the secrets of “Aggressive Maintenance” we will gain greater effectiveness and increased efficiency for our reconnaissance units in action.

More

Picture Sources: Cavalry Journal, March April, 1942

From an article by Captain Caesar F. Fiore, Cavalry as published in the Cavalry Journal, March April 1942.

Instead of the 2 ½-ton truck being used as the maintenance truck we consider it as a supply truck to carry spare parts and sub-assemblies. In addition, the supply truck can serve as a wrecker, car shop and general refueling station. The maintenance vehicle instead of being the 2 ½’-ton truck is the ¼-ton 4 x 4 outfitted and equipped to do first, second and limited third echelon repairs on any vehicle in the organization. The small sturdy and highly manuverable vehicle outfitted and equipped with cabinet and tools as shown in the accompanying photographs can do almost all of the work that has been done by the 2 ½-ton truck. The limit of effectiveness is not dependent upon the size of the maintenance vehicle but rather by the nature of the repair and the availability of replacement parts.A troop maintenance section could well be set up as follows:

a. One 2 ½-ton truck, with boom and winch, well stocked with replacement parts. This truck does rear line maintenance and towing only. It serves as a mother vehicle to carry the supplies that the smaller ¼-ton trucks will need for the actual front-line maintenance. b.Two or perhaps three ¼-ton 4 x 4 trucks outfitted with equipment as shown in accompanying photographs. c. A combat vehicle, either scout car or tank equipped with radio to receive calls from disabled vehicles. This vehicle xviii also serve to protect the maintenance section against local attacks.

To give an example of how this arrangement works let us assume that a reconnaissance troop is on a mission well forward of other divisional units and in the vicinity of enemy forces. The third platoon covering the right sector has a failure in one of its vehicles, let us say a burned out coil. By pre-arranged code symbols the third platoon commander radios troop headquarters “one scout car disabled,” giving the nature of the trouble and the location of the vehicle. In most cases the maintenance section radio will pick up the message direct. But in the case they do not, Troop Headquarters will send them the message. Immediately one of the Maintenance Peeps gathers the required replacement parts and races off to the scene. Using its high road and cross-country mobility, it covers the distance rapidly. If the damaged Scout Car is so situated as to cause difficulty in location, guides are sent out from the disabled vehicle to assist the Peep in arriving at its destination. Once the Peep has arrived at the scene, it is only a matter of moments until the damaged combat vehicle is repaired and has again taken its proper place in action. The Peep returns to the maintenance section and awaits new missions.

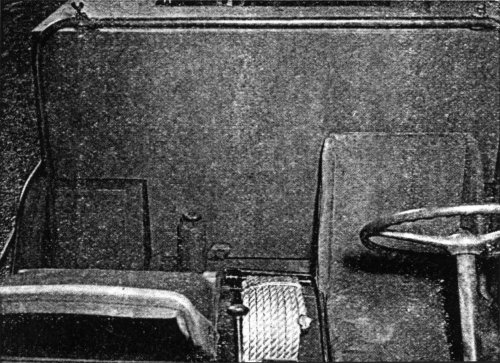

In this manner the great majority of motor failures can be reduced in the minimum of time and without unnecessarily exposing more expensive equipment. It can be readily seen that the result will be increased speed in reconnaissance; and where time is the watch word “Blitz Maintenance” must be exploited to the fullest degree. Photo No. 2

Photo No. 2

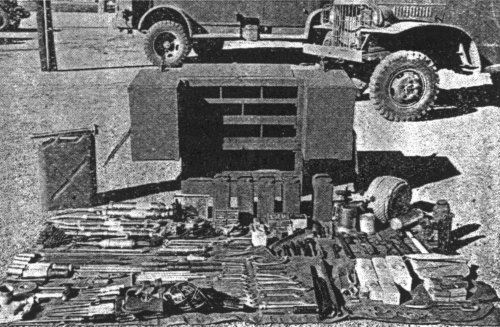

The cabinet itself is very easily constructed of white pine and waterproof plywood. The cabinet fits snugly into the ¼-ton 4 x 4 and one feature which of particular note is that the cabinet can be removed merely lifting it from its place in the vehicle. The only alteration necessary to the Peep is the removal oftwo brackets holding the top brace. These brackets are then attached to the top of the cabinet and the brace for the canvas top is then carried in the position shown in photograph No. 2. (Previous page.)  Photo No. 3

Photo No. 3

In photograph No. 3 a display of all tools and equipment carried in the cabinet is shown. It is not necessary to list here all the parts and tools shown. The weight of the cabinet and all items shown complete is appromately 320 pounds. This is not an excessive load for the ¼-ton 4 x 4 vehicle.

The framework of the cabinet is made of 2 x 2 white pine with metal L braces at critical points. The covering throughout including the slide door in the face of the cabinet is made of ¼ inch waterproof plywood. Small hinges, hasps and locks are easily available; the entire cabinet can be constructed at a cost of approximately $15.00. Note: Detailed specifications and drawings will be supplied upon request to CO., 92d Reconnaissance Squadron. Camp Funston, Kansas. Picture Sources: Cavalry Journal, March April, 1942